Unlocking the Potential of CNC Machining Parts for Your Business

In the ever-evolving landscape of modern manufacturing, cnc machining parts have emerged as a cornerstone technology that enables businesses to produce high-quality components with unparalleled precision and efficiency. As industries are increasingly adopting technological advances, CNC (Computer Numerical Control) machining is leading the way in revolutionizing how metal parts are fabricated. This article delves into the myriad benefits, applications, and advantages of CNC machining parts, providing essential insights for businesses aiming to thrive in today's competitive market.

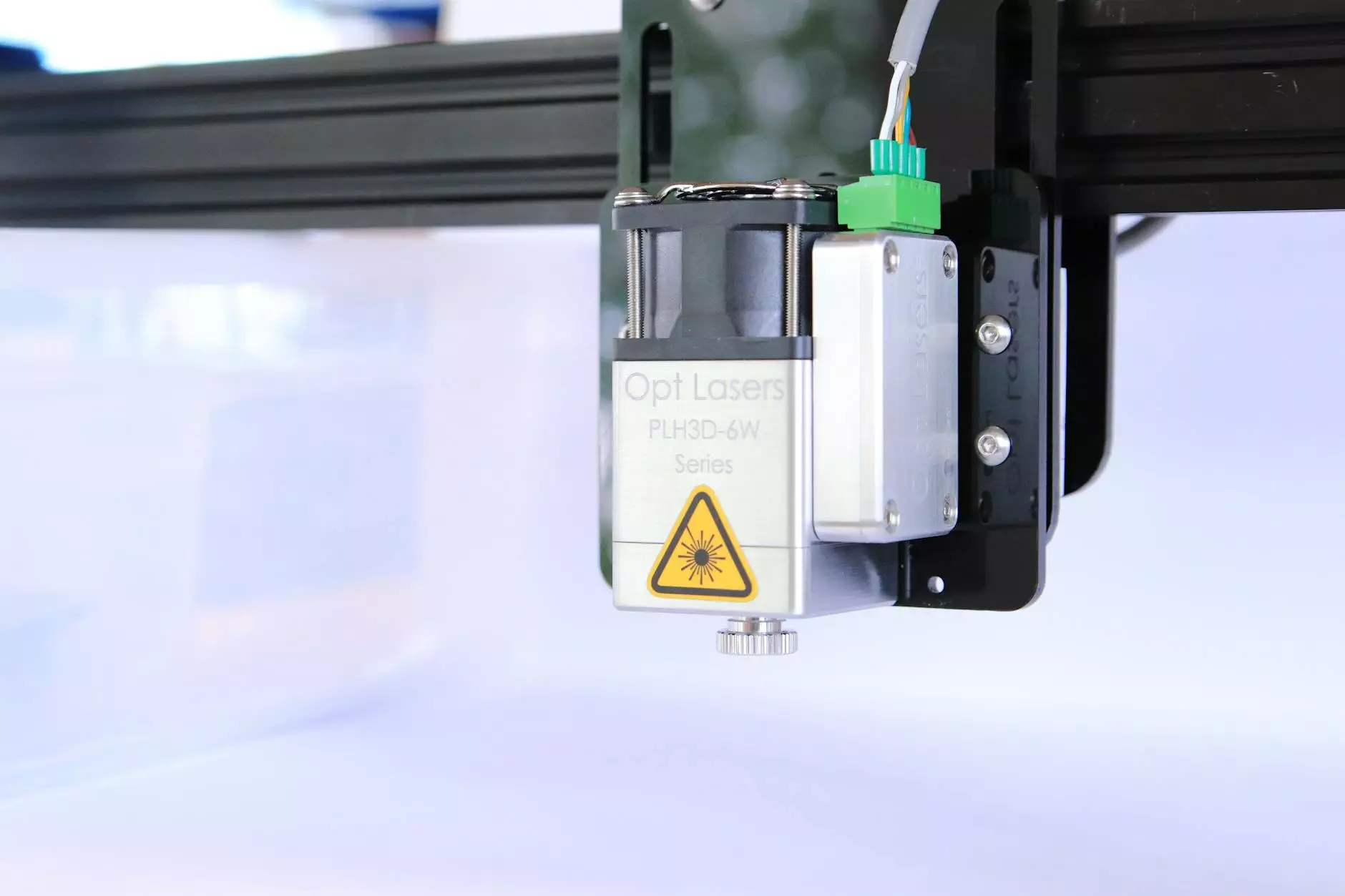

The Fundamentals of CNC Machining

CNC machining is a manufacturing process that utilizes computerized controls to operate tools and machinery. This technology allows for the automated production of intricate parts with tight tolerances. The CNC machine reads a code (typically G-code) generated from a 3D model, which guides the operational movements, ensuring precision and repeatability.

How CNC Machining Parts Work

The process begins with creating a 3D digital model using CAD (Computer-Aided Design) software. Once the design is finalized, it is translated into a machinable code that directs the CNC machine. Here’s a simplified breakdown of the CNC machining workflow:

- Design Phase: Create a detailed design using CAD software.

- Programming Phase: Convert the design into G-code.

- Machining Phase: Setup the CNC machine and load the material.

- Testing Phase: Run initial prototypes to ensure quality.

- Production Phase: Produce the required quantity of parts.

Benefits of Using CNC Machining Parts

The adoption of CNC machining parts in manufacturing offers numerous advantages that can significantly impact the efficiency and quality of production. Here are some key benefits:

- Precision and Accuracy: CNC machines produce parts that adhere to exact specifications, reducing the error margins often seen with traditional machining techniques.

- Consistency: Once programmed, CNC machines can consistently replicate high-quality parts, ensuring uniformity across all manufactured products.

- Versatility: CNC machining is applicable to a wide variety of materials, including metals, plastics, and composites, making it suitable for a myriad of industries.

- Cost-Effectiveness: While the initial investment may be higher, CNC machining generally leads to lower labor costs and higher productivity, allowing for better long-term ROI.

- Complex Geometries: CNC machining can easily handle complex shapes that would be difficult or impossible to achieve with manual machining.

- Minimal Waste: The precision of CNC machining means less material waste, making it an environmentally friendly manufacturing option.

Applications of CNC Machining Parts in Various Industries

CNC machining parts find applications across a wide range of industries due to their inherent flexibility. Here's a closer look at some sectors that benefit significantly from this technology:

Aerospace Industry

The aerospace industry demands high precision and reliability. CNC machining parts are critical in manufacturing components such as turbine blades, landing gears, and brackets, all of which need to withstand extreme conditions and require meticulous accuracy.

Automotive Industry

In the automotive sector, CNC machining parts are used to produce intricate components, including engine blocks, transmission cases, and suspension systems. The ability to create lightweight yet durable parts aids in fuel efficiency and enhances vehicle performance.

Medical Equipment Manufacturing

The medical field requires equipment that must adhere to strict regulations and high standards. CNC machining is employed to manufacture surgical instruments, implants, and dental devices, ensuring they meet the necessary precision and durability requirements.

Electronics and Telecommunications

The production of enclosures, connectors, and circuit boards in the electronics industry benefits from CNC machining’s ability to create complex shapes and designs that often incorporate multiple features in one component.

Industrial Machinery

CNC machining is prevalent in the manufacture of industrial machinery components such as gears, shafts, and housings, which require not only accuracy but also the ability to withstand heavy operational stresses.

Choosing the Right CNC Machining Parts Supplier

Selecting a reliable supplier for CNC machining parts is critical for any business looking to enhance its manufacturing capabilities. Here are some factors to consider:

- Experience and Expertise: Look for suppliers with a proven track record in the industry. Experience translates to knowledge of best practices and potential solutions to common problems.

- Quality Standards: Ensure that the supplier adheres to industry standards and certifications, such as ISO. This guarantees that components meet required specifications.

- Material Options: A good supplier should offer a wide range of materials to meet various applications. This flexibility allows businesses to optimize for performance and cost.

- Technology and Equipment: Suppliers should invest in modern CNC machinery and technology, allowing for the production of high-quality, complex parts.

- Customer Support: An excellent supplier provides support throughout the manufacturing process, addressing any issues that arise and offering advice on best practices.

The Future of CNC Machining Parts

As technology continues to advance, the future of cnc machining parts looks promising. Innovations such as automation, artificial intelligence, and machine learning are set to transform the CNC machining landscape further. These advancements will likely lead to even higher levels of efficiency, accuracy, and customization, enabling businesses to meet the rising demands of a dynamic market.

Embracing Industry 4.0

The integration of Industry 4.0 principles, including IoT (Internet of Things) and smart manufacturing, is expected to enhance the capabilities of CNC machines. Features like real-time monitoring, predictive maintenance, and advanced data analytics will allow manufacturers to optimize operations and improve decision-making processes.

Conclusion

In summary, CNC machining parts play an integral role in modern manufacturing, offering unmatched precision, versatility, and efficiency. The benefits are profound, from reducing waste to ensuring the production of consistent, high-quality components. As industries continue to evolve, investing in CNC machining technology and selecting the right suppliers will be paramount for businesses aiming to thrive in a competitive environment. By understanding the importance of these parts, businesses can unlock a new level of production capabilities and position themselves for future success.

For more information about CNC machining parts and how they can benefit your business, visit deepmould.net.