Maximizing Efficiency and Reliability in Diesel Engine Parts and Bulk Fuel Transport Pumps

In today’s fast-paced industrial landscape, the importance of high-quality diesel engine parts and effective spare parts suppliers cannot be overstated. As businesses strive to enhance operational efficiency, reduce downtime, and cut costs, understanding the critical components powering diesel-powered machinery is essential. Among these components, the bulk fuel transport pump plays a pivotal role in ensuring smooth fuel delivery, safeguarding equipment, and maintaining optimal productivity. This article delves into the vital aspects of diesel engine part procurement, the significance of reliable spare parts suppliers, and the crucial function of bulk fuel transport pump in modern diesel operations.

Understanding the Significance of Diesel Engine Parts in Modern Industry

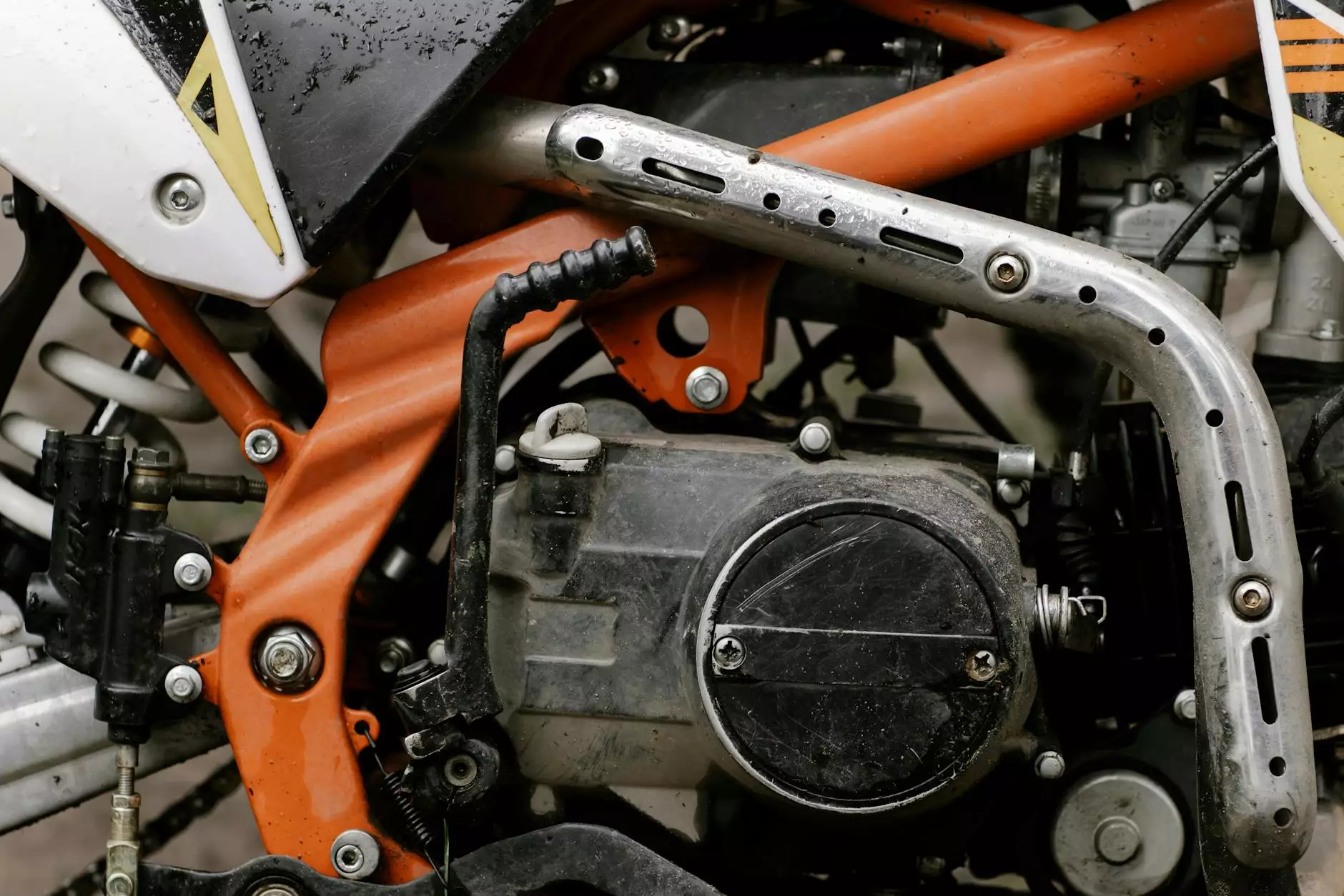

Diesel engines have long been the backbone of various industrial sectors, including construction, agriculture, transportation, and energy generation. Their durability, fuel efficiency, and capacity for heavy-duty applications make them indispensable. Consequently, the diesel engine parts must meet stringent quality standards to ensure consistent performance and longevity.

High-quality engine components such as fuel injectors, pistons, valves, crankshafts, and turbochargers directly influence engine efficiency, emissions, and operational lifespan. Using inferior parts can lead to increased maintenance costs, unplanned downtime, and potential safety hazards. Therefore, partnering with reputable spare parts suppliers who can provide genuine, certified parts is a top priority for most diesel-powered businesses.

Innovation in diesel engine technology, including electronically controlled systems and advanced combustion processes, necessitates sourcing compatible, state-of-the-art components. This focus on quality guarantees that engines operate at peak efficiency, reduce environmental impact, and comply with evolving regulations.

Choosing Reliable Spare Parts Suppliers for Diesel Engines

Identifying the right spare parts supplier is fundamental to maintaining a resilient diesel operation. An ideal supplier offers not only a broad inventory of genuine parts but also dependable delivery, technical support, and competitive pricing. Here are critical factors to consider when selecting your supplier:

- Product Authenticity and Certification: Ensure that parts are OEM (Original Equipment Manufacturer) certified to guarantee compatibility and durability.

- Inventory Range: A comprehensive catalog covering all essential diesel engine components, from filters to electronic control units.

- Supply Chain Reliability: Timely delivery and stock availability to minimize operational interruptions.

- Technical Expertise: Access to knowledgeable staff capable of advising on proper parts selection and maintenance procedures.

- Customer Support and Warranty: Robust after-sales support and warranty policies that safeguard your investment.

Establishing a strong relationship with a reputable spare parts supplier can dramatically improve your maintenance planning, reduce costs, and extend the lifespan of your diesel machinery.

The Critical Role of Bulk Fuel Transport Pumps in Diesel Operations

Efficient fuel management is fundamental for diesel engine performance. Central to this process is the bulk fuel transport pump, a specialized device designed for transferring large volumes of diesel efficiently, safely, and reliably. This equipment is critical for industries that rely on bulk fuel storage and consumption, such as transportation fleets, power plants, and industrial facilities.

The bulk fuel transport pump ensures consistent fuel flow from storage tanks to engines or dispensing points, minimizing wastage and contamination risks. Proper operation of these pumps directly affects fuel economy, engine health, and environmental compliance.

Modern bulk fuel transport pumps incorporate advanced features such as automated controls, pressure regulation, and safety shut-offs, contributing to smoother operations and higher safety standards. When selecting a pump, considerations include flow capacity, compatibility with diesel fuel types, ease of maintenance, and compliance with industry regulations.

Benefits of Using Advanced Bulk Fuel Transport Pumps

- Enhanced Efficiency: High-capacity pumps reduce fueling times, increasing operational productivity.

- Cost Savings: Reliable pumps decrease maintenance costs through durable materials and efficient design, preventing leaks and spills.

- Safety Improvements: Incorporating safety features like automatic shut-off and pressure sensors minimizes explosion risks and environmental hazards.

- Environmental Compliance: Modern pumps are designed to meet strict environmental regulations by controlling emissions and preventing fuel leaks.

- Operational Flexibility: Pumps adaptable to various fuel storage systems and flow rates support diverse industrial needs.

Integrating Bulk Fuel Transport Pumps into Your Diesel Business Strategy

To maximize the benefits of bulk fuel transport pumps, businesses should consider comprehensive planning and integration strategies:

- Assess Your Fuel Volume Needs: Accurate assessment ensures selecting a pump with suitable capacity and pressure ratings.

- Invest in Quality Equipment: Prioritize pumps from reputable manufacturers with proven performance records to guarantee durability and reliability.

- Regular Maintenance and Testing: Routine inspections, cleaning, and testing prevent downtime and maintain efficiency.

- Staff Training: Proper training on pump operation and safety protocols safeguards personnel and assets.

- Monitoring and Data Management: Implement systems that track fuel transfer metrics for better inventory control and operational oversight.

Future Trends in Diesel Engine Parts and Fuel Transport Technology

The diesel industry is continually evolving with innovations aimed at improving sustainability, efficiency, and automation. Key trends include:

- Smart Diesel Engine Components: Integration of sensors and IoT technology for real-time diagnostics and predictive maintenance.

- Eco-Friendly Fuel Systems: Development of cleaner fuel injection and exhaust after-treatment systems to reduce emissions.

- Automated Fuel Management: Use of automated pumps and monitoring software to optimize fuel transfer and inventory management.

- Sustainable Energy Alternatives: Exploring hybrid systems and alternative fuels as complements or replacements to traditional diesel engines.

- Enhanced Safety Protocols: Implementation of advanced safety features and training to mitigate operational risks.

Staying ahead of these trends can provide competitive advantages, ensure regulatory compliance, and promote environmentally responsible business practices.

Conclusion: Building a Robust Diesel Business for Long-Term Success

In conclusion, success in the diesel industry depends heavily on your ability to source high-quality diesel engine parts, collaborate with trusted spare parts suppliers, and employ efficient bulk fuel transport pumps. These elements collectively ensure operational reliability, cost efficiency, safety, and environmental sustainability. Investing in advanced equipment and strategic partnerships equips your business to face future challenges, capitalize on technological innovations, and achieve long-term growth.

By focusing on quality, safety, and efficiency, your organization can maintain a competitive edge in the dynamic diesel sector, ultimately leading to increased profitability and industry leadership.