Unlocking Excellence in Metal Fabrication: Your Ultimate Guide to the Leading Lathe Turning Parts Factory at DeepMould.net

In the world of manufacturing and industrial production, precision, quality, and reliability are the cornerstones of success. At the heart of this dynamic industry stands the metal fabrication sector, where innovative processes and cutting-edge technology combine to produce impeccable components that power machinery, automotive, aerospace, and other critical sectors.

Among the many specialized services offered within this domain, lathe turning parts factory services have become particularly vital. As a premier metal fabricator, DeepMould.net has established itself as a leader, delivering top-quality lathe turning components with unmatched precision, durability, and efficiency. This in-depth guide explores why DeepMould.net is your ideal partner for all your metal fabrication needs, especially in the lathe turning parts factory segment.

Understanding the Significance of a Lathe Turning Parts Factory

The lathe turning parts factory plays a crucial role in modern manufacturing. Lathe turning is a fundamental machining process where a cutting tool removes material from a rotating workpiece to shape it into desired forms and dimensions. These parts are indispensable components in various machinery — from simple tools to complex aerospace systems.

A lathe turning parts factory specializes in producing these precision components, ensuring they meet stringent quality standards, specifications, and durability requirements. The ability to manufacture complex geometries, maintain tight tolerances, and uphold high-volume production capabilities makes these factories invaluable to multiple industries.

Why Choose DeepMould.net as Your Lathe Turning Parts Factory Partner

1. Extensive Expertise in Metal Fabrication

DeepMould.net boasts over two decades of experience in the field of metal fabrication. Our team of skilled engineers and technicians has mastered a broad spectrum of manufacturing processes, including precision lathe turning, milling, grinding, and surface finishing. This vast expertise ensures that every lathe turning part we produce adheres to the highest standards of quality and performance.

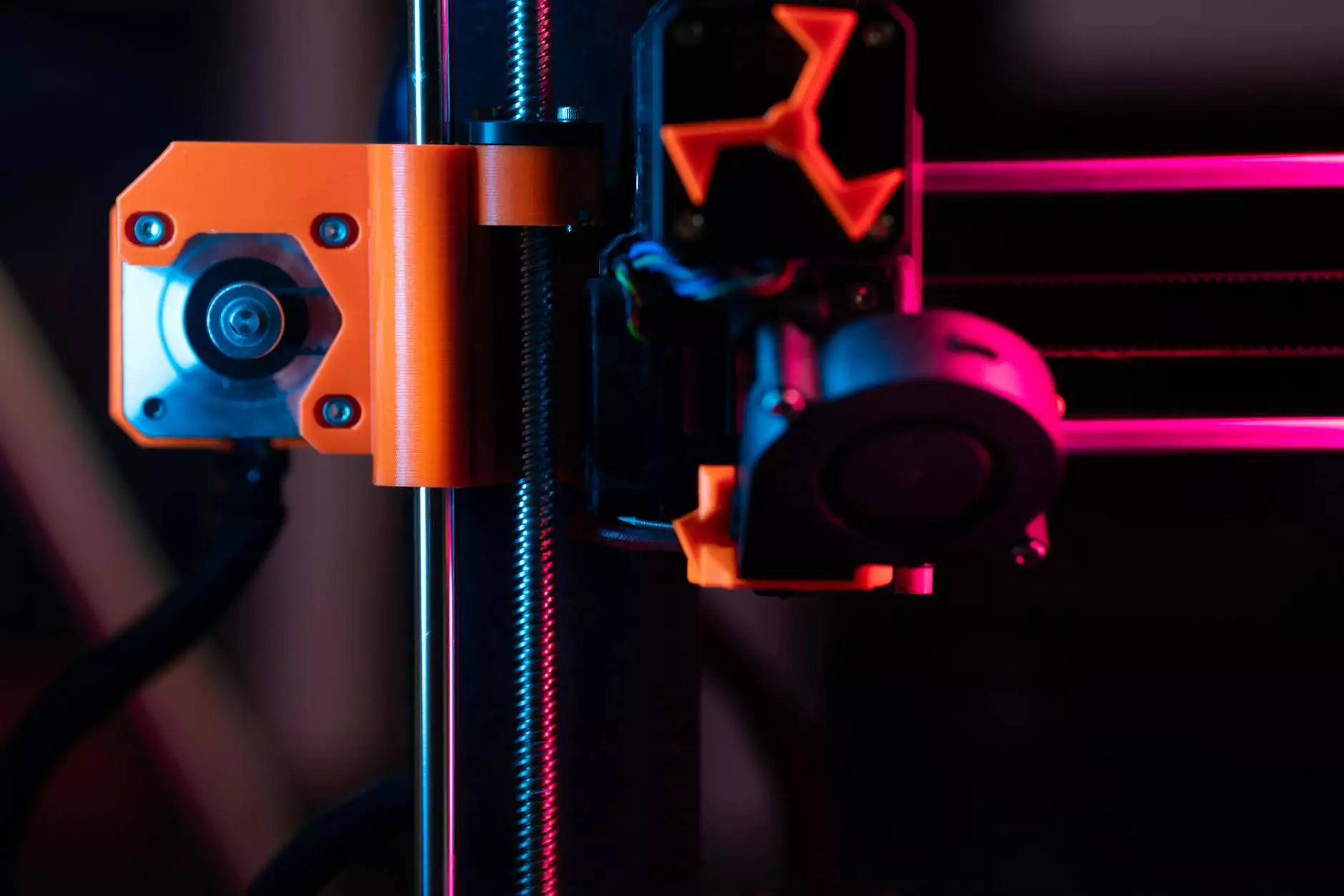

2. Advanced Manufacturing Technologies

To achieve superior results, DeepMould.net invests heavily in cutting-edge equipment such as CNC lathes, multi-axis machining centers, and robotic automation. These technologies enable us to produce complex lathe turning parts factory components with exceptional accuracy, consistency, and repeatability, even in high-volume production runs.

3. Comprehensive Material Selection

We work with a wide array of materials, including stainless steel, carbon steel, aluminum, brass, copper, and specialized alloys. Our material experts assist clients in choosing the optimal material for their specific application, ensuring maximum performance and longevity of the lathe turning parts.

4. Strict Quality Control Processes

Quality assurance is embedded into every stage of our manufacturing process. From raw material inspection to final product testing, our rigorous quality control protocols guarantee that each lathe turning part factory component leaves our facility meeting international standards such as ISO 9001, ASTM, and TS16949.

5. Customization and Rapid Prototyping

Whether you need a small batch of prototype parts or mass production, DeepMould.net offers flexible manufacturing solutions. Our ability to customize designs, combined with rapid prototyping capabilities, accelerates project timelines and reduces overall costs.

The Manufacturing Process at DeepMould.net: From Design to Delivery

Step 1: Design and Engineering Analysis

Our process begins with a comprehensive review of your specifications. Using advanced CAD/CAM software, our engineers optimize designs for manufacturability, ensuring the final lathe turning parts meet your performance and quality expectations.

Step 2: Material Procurement and Preparation

We source premium raw materials from trusted suppliers worldwide. Material certification accompanies every batch, providing transparency and traceability throughout the manufacturing cycle.

Step 3: Precision Machining

At the core of our operation is our state-of-the-art CNC lathe machines. These machines precisely cut and shape the raw materials, executing complex geometries with tolerances as tight as ±0.005mm. Our skilled operators oversee the process to maintain optimal performance and quality.

Step 4: Surface Finishing and Quality Inspection

After machining, parts undergo surface treatments such as polishing, anodizing, or plating to improve corrosion resistance and aesthetic appeal. Every component is subjected to detailed inspection, including dimensional measurement, hardness testing, and visual assessment, ensuring compliance with specifications.

Step 5: Packaging and Delivery

Our packaging is designed to prevent damage during transit, using custom foam inserts and protective films. We offer flexible shipping options worldwide, ensuring timely delivery of your lathe turning parts directly to your facility or project site.

The Benefits of Partnering with DeepMould.net for Your Lathe Turning Parts Factory Needs

- Unparalleled Quality: We deliver components that meet or exceed industry standards, ensuring your machinery operates smoothly.

- Cost Efficiency: Our optimized processes and bulk manufacturing capability reduce costs without compromising quality.

- Fast Turnaround: Short lead times and rapid prototyping accelerate your project timelines.

- Technical Support: Our engineering team provides end-to-end support, from design consultation to post-production inspection.

- Global Reach: We serve clients across multiple continents, backed by reliable logistics and excellent customer service.

Industries that Benefit from Our Lathe Turning Parts

The versatility of our metal fabrication services makes us a vital partner for numerous industries, including:

- Aerospace: for precision-engineered aviation components.

- Automotive: for manufacturing engine parts, shafts, and fasteners.

- Electronics: for creating specialized enclosures and connectors.

- Medical Devices: for producing high-precision surgical instruments.

- Industrial Machinery: ensuring operational reliability with high-tolerance components.

Environmental Responsibility and Sustainable Manufacturing

DeepMould.net is committed to sustainable manufacturing practices. We optimize material usage, recycle waste materials, and utilize energy-efficient equipment to reduce our environmental footprint. These practices ensure that your lathe turning parts are not only of the highest quality but also produced responsibly.

Partner with the Best: Your Trusted Metal Fabricator & Lathe Turning Parts Factory at DeepMould.net

Whether you require small precision components or large-scale production, DeepMould.net offers comprehensive solutions tailored to your needs. Our commitment to excellence, innovative techniques, and customer-centric approach make us the preferred choice in the metal fabrication industry.

Contact us today to discuss your project requirements. Experience the difference that industry-leading lathe turning parts factory services can make in elevating your manufacturing capabilities and industry competitiveness.