Unlocking Business Potential in Electronics and 3D Printing: Your Complete Guide to Success and Foundational Equipment

In today’s rapidly evolving industrial landscape, businesses operating within the realms of electronics and 3D printing are experiencing unprecedented growth and transformation. Whether you're a startup or an established enterprise, understanding the key dynamics of these sectors is vital to achieving competitive edge and sustainable success.

The Rise of Electronics and 3D Printing Industries

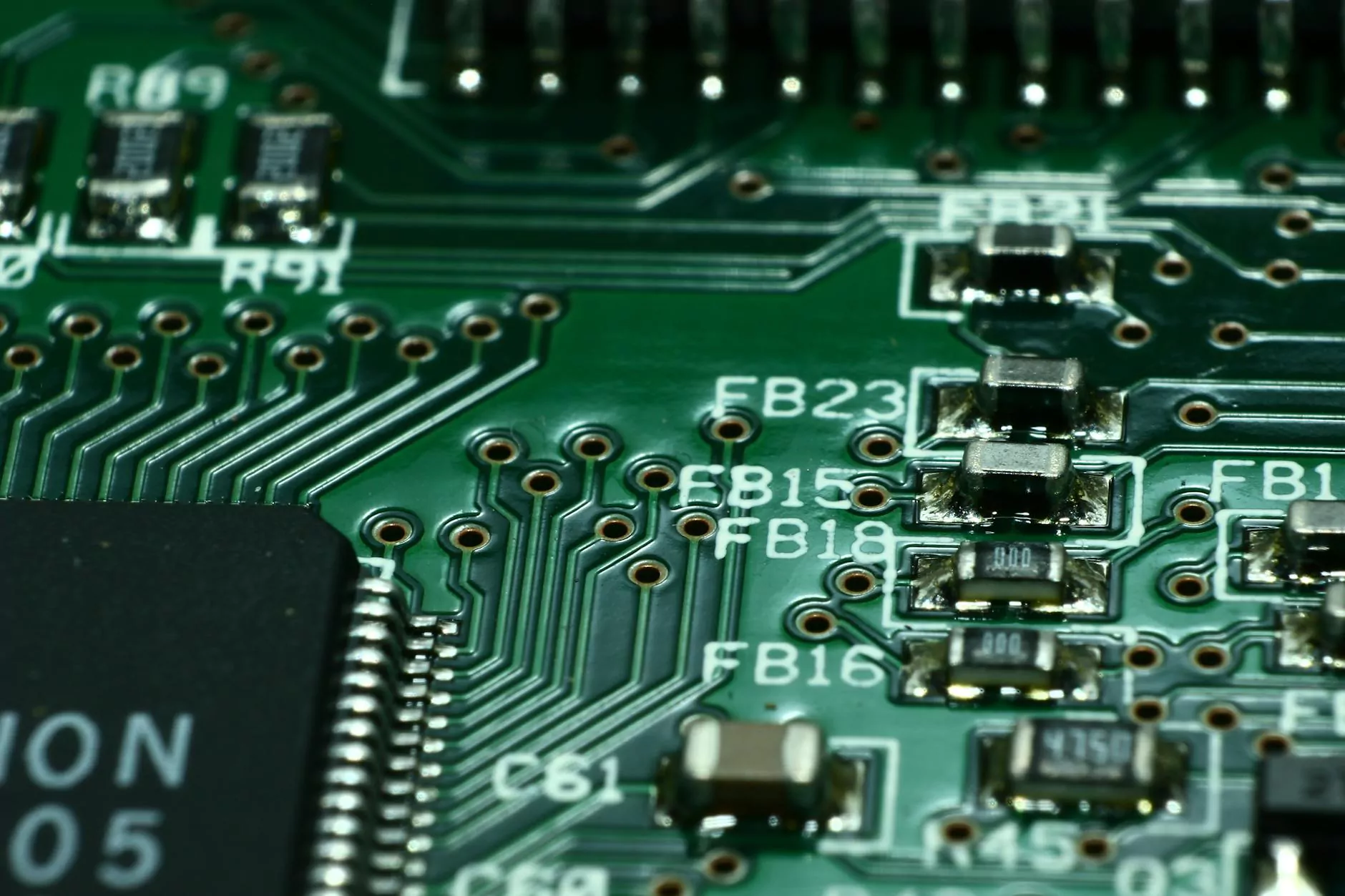

The electronics industry continues to be a cornerstone of technological innovation, fueling advancements in consumer devices, industrial machinery, healthcare equipment, and communication systems. Meanwhile, 3D printing—also known as additive manufacturing—has revolutionized product development, prototyping, and custom manufacturing, reducing costs and lead times significantly. Together, these sectors offer immense opportunities for entrepreneurs, manufacturers, and tech enterprises alike.

Strategic Business Development in Electronics and 3D Printing

- Invest in Cutting-Edge Technology: Staying ahead in electronics and 3D printing requires continuous investment in the latest machinery, software, and materials. This ensures quality, efficiency, and innovation leadership.

- Develop Niche Markets: Identifying underserved niches such as specialized electronics components or custom 3D printed parts can unlock high-margin opportunities and reduce competition.

- Build Robust Supply Chains: Securing reliable sources for raw materials and components ensures uninterrupted operations and quicker response times to market demands.

- Focus on Sustainability: Incorporating eco-friendly materials and energy-efficient processes not only benefits the environment but also enhances your brand reputation among conscious consumers.

- Prioritize Quality Assurance: Implement rigorous testing and certification practices to ensure compliance with global standards, thereby building customer trust and loyalty.

Leveraging Advanced Manufacturing Equipment for Business Growth

At the core of successful operations in these sectors lies the deployment of sophisticated manufacturing equipment. For businesses involved in producing large-scale storage solutions and raw materials handling, equipment such as cement silos plays a crucial role.

Why a Cement Silo for Sale Is Essential for Your Business

In industrial environments, particularly those involved in construction, manufacturing, or materials handling, a cement silo for sale provides several strategic advantages:

- Efficient Storage & Dispensing: Cement silos allow for bulk storage, minimizing handling and reducing logistics costs.

- Enhanced Material Management: They facilitate precise dispensing and mixing, optimizing material usage and reducing waste.

- Operational Safety: Modern cement silos are equipped with safety features like overfill protection and weather-resistant designs, ensuring safe operations.

- Cost Savings & Return on Investment: Purchasing a high-quality cement silo for sale can significantly lower operational costs in the long term.

The Crucial Role of Equipment Selection in Business Success

Selecting the right manufacturing equipment, especially when considering a cement silo for sale, impacts productivity, quality, and profitability. When choosing a silo, consider:

- Capacity & Size: Match the silo capacity to your production volume to avoid unnecessary costs or operations disruptions.

- Material Durability: Opt for silos constructed with corrosion-resistant materials, especially if handling chemical additives or other aggressive materials.

- Automation & Control Systems: Modern silos equipped with automated control systems enable precise operation, reducing labor costs and errors.

- Maintenance & Support: Reliable after-sales service and easy maintenance are vital for sustained operations.

Integrating Electronics and 3D Printing with Material Handling Solutions

The synergy between electronics, 3D printing, and material handling equipment like cement silos can open new realms of business innovation:

- Custom Manufacturing: Use 3D printing technology to produce bespoke components for your silos and related machinery, increasing customization options.

- Smart Electronics Integration: Incorporate IoT sensors into silos for real-time monitoring of fill levels, temperature, and structural integrity, leading to smarter asset management.

- Prototyping & R&D: Rapidly prototype new designs or modifications to existing equipment with 3D printing, accelerating development cycles.

Market Insights for Buying a Cement Silo for Sale

When considering the purchase of a cement silo for sale, market research becomes crucial. Here are some tips:

- Quality & Certification: Choose suppliers offering certified, high-quality silos compliant with safety and environmental standards.

- Price & Warranty: Compare prices among reputable suppliers, considering warranties and after-sales support as part of the value proposition.

- Customization Options: Ensure the supplier can customize the silo dimensions and features to suit your operational needs.

- Delivery & Installation: Verify lead times, logistics, and installation services to minimize downtime.

Leading Suppliers and Manufacturers of Cement Silos

Research and choose trusted manufacturers known for durability, innovation, and competitive pricing. Leading providers often offer comprehensive services including:

- Design & Engineering Support: Customized solutions tailored to specific business needs.

- Quality Assurance & Compliance: Products tested for longevity and safety.

- After-Sales Service: Maintenance support, spare parts, and technical assistance.

How Investing in Proper Equipment Elevates Your Business Performance

Investments in equipment like a cement silo for sale should align with your broader business strategy. Benefits include:

- Increased Production Efficiency: Streamlined operations reduce bottlenecks and enhance throughput.

- Cost Reduction: Bulk storage and automated control minimize material wastage and labor costs.

- Quality Consistency: Precise dispensing and storage maintain high product quality standards.

- Scalability: Flexible equipment options allow for business growth and diversification.

Growth Tips for Businesses in Electronics, 3D Printing, and Material Handling

To position your business for long-term success:

- Stay Ahead with Tech Trends: Keep updated on technological innovations in electronics, additive manufacturing, and automation.

- Expand Product & Service Offerings: Diversify to include new electronics components, custom 3D printed parts, or advanced material handling solutions.

- Invest in Workforce Skills: Train your team in the latest manufacturing techniques, safety standards, and digital tools.

- Forge Strategic Partnerships: Collaborate with suppliers, research institutions, and industry associations for shared growth and innovation.

Conclusion: Power Your Business with the Right Tools & Strategic Vision

Success in the electronics and 3D printing markets hinges not only on innovation but also on choosing the right infrastructure and equipment. A cement silo for sale represents a vital asset for many manufacturing and construction businesses, streamlining operations and optimizing resource utilization. By investing wisely, integrating advanced technologies, and maintaining a focus on quality and sustainability, your business can thrive amidst fierce competition.

Whether expanding your manufacturing capacity or upgrading existing facilities, reliable equipment procurement—especially top-tier cement silos—is a strategic move that yields long-term benefits, from operational efficiencies to market competitiveness.

Empower your enterprise today with informed decisions, cutting-edge solutions, and a visionary approach. Leverage the synergies of electronics, 3D printing, and robust material handling equipment to carve out your unique space in the industry and achieve unparalleled growth.